Обсуждение участника:SAMSON — различия между версиями

SAMSON (обсуждение | вклад) |

SAMSON (обсуждение | вклад) (→ПЕРЕВОДИМ_Оглавление) |

||

| (не показано 6 промежуточных версий этого же участника) | |||

| Строка 1: | Строка 1: | ||

| + | |||

| + | |||

| + | == ПЕРЕВОДИМ_Оглавление == | ||

| + | |||

Оглавление | Оглавление | ||

| + | |||

Благодарности | Благодарности | ||

| − | Аннотация | + | |

| + | Аннотация | ||

| + | |||

Глава I. ВВЕДЕНИЕ | Глава I. ВВЕДЕНИЕ | ||

| + | :1.1 Background | ||

| + | :1.2 Purpose and Overview | ||

| − | 1. | + | Глава II. Braided Pneumatic Actuators |

| + | :2.1 Physical Characteristics | ||

| + | :2.2 Geometric and Static Model | ||

| + | :2.3 Static Model Verification | ||

| + | :2.4 Dynamic Model | ||

| − | 1.2 | + | Глава III. Simulation |

| + | :3.1 Simulation Overview | ||

| + | :3.2 Equations of Motion | ||

| + | :3.3 Valve Model | ||

| + | :3.4 Dynamic Model Verification | ||

| − | + | Глава IV. Robot Hardware | |

| + | :4.1 System Overview | ||

| + | :4.2 Leg Design | ||

| + | :4.3 Valves | ||

| + | :4.4 Force Sensors | ||

| + | :4.5 Angle Sensors | ||

| − | 2. | + | Глава V. Control |

| + | :5.1 Control Architecture and Control Laws | ||

| + | :5.2 Control Program | ||

| + | :5.3 Inverse Kinematics | ||

| − | 2. | + | Глава VI. Results and Discussion |

| + | :6.1 Desired Walking Behavior | ||

| + | :6.2 Tuning | ||

| + | :6.3 Walking Results | ||

| + | :6.4 Robot Limitations | ||

| + | :6.5 Derivative Control | ||

| − | 2.3 | + | Глава VII. Conclusion |

| + | :7.1 It Walks! | ||

| + | :7.2 Semi-Observed Speculation | ||

| + | :7.3 Future work | ||

| − | + | ---- | |

| − | + | ||

| − | + | Приложение A: Simulation Code | |

| − | + | :A.1 Actuator.cpp | |

| − | + | ||

| − | + | Приложение B: Controller Code | |

| − | + | :B.1 Control.cpp | |

| − | + | :B.2 Def.h | |

| − | + | :B.3 Hardware.cpp | |

| − | + | :B.4 Predict.dat | |

| − | + | :B.5 Gain.dat | |

| − | + | ||

| − | + | Приложение C: Robot Hardware | |

| − | + | :C.1 Strain Gage Amplifier | |

| − | + | :C.2 Wiring | |

| − | + | :C.3 Mechanical Drawings | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | A.1 Actuator.cpp | ||

| − | |||

| − | B.1 Control.cpp | ||

| − | B.2 Def.h | ||

| − | B.3 Hardware.cpp | ||

| − | |||

| − | B.4 Predict.dat | ||

| − | B.5 Gain.dat | ||

| − | |||

| − | C.1 Strain Gage Amplifier | ||

| − | C.2 Wiring | ||

| − | C.3 Mechanical Drawings | ||

| − | |||

| + | '''Литература''' | ||

---- | ---- | ||

'''Список таблиц''' | '''Список таблиц''' | ||

| − | + | ||

| − | + | :Таблица 4.1 : Transducer sensitivity and error | |

| − | + | :Таблица 6.1 : Joint range of motion | |

| − | + | :Таблица 6.2 : Time parameters for walking motion | |

| − | + | :Таблица 6.3 : Walking motion control gains | |

| + | :Таблица 6.4 : Passivity and average duty cycles of each valve | ||

| + | |||

| + | ---- | ||

| + | |||

| + | '''Список иллюстраций''' | ||

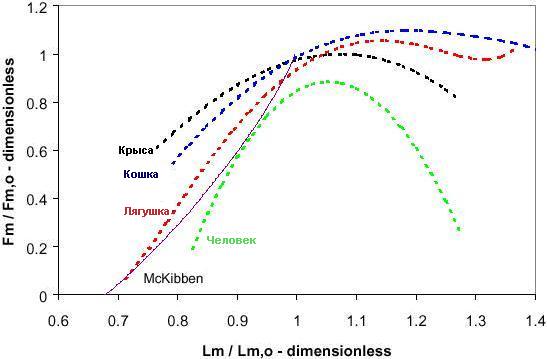

| + | :Иллюстрация 1.1 : Dimensionless force-length properties of actuators and biological muscles | ||

| + | :Иллюстрация 2.1 : Photograph of inflated and uninflated actuators | ||

| + | :Иллюстрация 2.2 : Actuator dimensions | ||

| + | :Иллюстрация 2.3 : Geometric schematic of actuators | ||

| + | :Иллюстрация 2.4 : Mesh geometry | ||

| + | :Иллюстрация 2.5 : Revised actuator geometry schematic | ||

| + | :Иллюстрация 2.6 : Pressure, Length, Force, Stiffness Relationship for a BPA | ||

| + | :Иллюстрация 2.7 : Static model verification schematic | ||

| + | :Иллюстрация 2.8 : Plot of Force vs. Length for a BPA with constant internal mass of air | ||

| + | :Иллюстрация 2.9 : Pressure Increase vs. Length – constant mass system | ||

| + | :Иллюстрация 2.10 : Plot of Force vs. Length – constant air mass – Exp. vs. Theor. results | ||

| + | :Иллюстрация 2.11 : Plot of Effectiveness vs. Pressure | ||

| + | :Иллюстрация 2.12 : Plot of Force vs. Length – Exp. vs. Theor. Results – (effectiveness) | ||

| + | :Иллюстрация 2.13 : Plot of Force vs. Length – Constant Pressure System | ||

| + | :Иллюстрация 2.14 : Dynamic model schematic | ||

| + | :Иллюстрация 3.1 : Simulation overview schematic | ||

| + | :Иллюстрация 3.2 : Detailed simulation schematic | ||

| + | :Иллюстрация 3.3 : Actuator equation of motion schematic | ||

| + | :Иллюстрация 3.4 : Flow curve for Matrix 758 3-way valve | ||

| + | :Иллюстрация 3.5 : Dynamic model verification schematic | ||

| + | :Иллюстрация 3.6 : Length vs. Time – 60 psi constant mass – 6 lb load - measured | ||

| + | :Иллюстрация 3.7 : Length vs. Time – 60 psi constant mass – 6 lb load - simulation | ||

| + | :Иллюстрация 3.8 : Length vs. Time – 80 psi constant mass – 11 lb load - measured | ||

| + | :Иллюстрация 3.9 : Length vs. Time – 80 psi constant mass – 11 lb load - simulation | ||

| + | :Иллюстрация 3.10 : Length vs. Time – 60 psi constant mass – 11 lb load - measured | ||

| + | :Иллюстрация 3.11 : Length vs. Time – 60 psi constant mass – 11 lb load - simulation | ||

| + | :Иллюстрация 3.12 : PWM valve model verification schematic | ||

| + | :Иллюстрация 3.13 : Commanded vs. Actual duty cycles – Matrix 758 3-way valve | ||

| + | :Иллюстрация 3.14 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 5 lb load - measured | ||

| + | :Иллюстрация 3.15 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 5 lb load - simulation | ||

| + | :Иллюстрация 3.16 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 1 lb load - measured | ||

| + | :Иллюстрация 3.17 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 1 lb load - simulation | ||

| + | :Иллюстрация 3.18 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 15 lb load - measured | ||

| + | :Иллюстрация 3.19 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 15 lb load - simulation | ||

| + | :Иллюстрация 3.20 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 1 lb load - measured | ||

| + | :Иллюстрация 3.21 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 1 lb load - simulation | ||

| + | :Иллюстрация 3.22 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 5 lb load - measured | ||

| + | :Иллюстрация 3.23 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 5 lb load - simulation | ||

| + | :Иллюстрация 4.1 : Robot hardware schematic | ||

| + | :Иллюстрация 4.2 : Photograph of robot | ||

| + | :Иллюстрация 4.3 : CAD model and photograph of robot leg | ||

| + | :Иллюстрация 4.4 : CAD model and photograph of hip translational joint | ||

| + | :Иллюстрация 4.5 : CAD model and photograph of hip rotational joint | ||

| + | :Иллюстрация 4.6 : Schematic of inlet valve | ||

| + | :Иллюстрация 4.7 : Schematic of exhaust valve | ||

| + | :Иллюстрация 4.8 : Current vs. time for inlet valve | ||

| + | :Иллюстрация 4.9 : Current vs. time for exhaust valve | ||

| + | :Иллюстрация 4.10 : Force sensor classic analysis schematic | ||

| + | :Иллюстрация 4.11 : Force sensor FEA results | ||

| + | :Иллюстрация 4.12 : Photograph of force sensors | ||

| + | :Иллюстрация 4.13 : Photograph of strain gage amplifier | ||

| + | :Иллюстрация 4.14 : Transducer calibration plot | ||

| + | :Иллюстрация 4.15 : Photograph of completed force measurement system | ||

| + | :Иллюстрация 4.16 : Photograph of completed angle measurement systems | ||

| + | :Иллюстрация 5.1 : Labeled schematic of a joint | ||

| + | :Иллюстрация 5.2 : Block diagram of the control algorithm | ||

| + | :Иллюстрация 5.3 : ISR schematic | ||

| + | :Иллюстрация 5.4 : Inverse kinematics schematic | ||

| + | :Иллюстрация 6.1 : Desired foot positions for walking motion | ||

| + | :Иллюстрация 6.2 : Sequential video frames of the leg during walking motion | ||

| + | :Иллюстрация 6.3 : Desired and actual x-y foot paths: Test 1 | ||

| + | :Иллюстрация 6.4 : Desired and actual joint angles vs. time: Test 1 | ||

| + | :Иллюстрация 6.5 : Actuator force vs. time | ||

| + | :Иллюстрация 6.6 : Desired and actual joint stiffness vs. time | ||

| + | :Иллюстрация 6.7 : Joint torque vs. time | ||

| + | :Иллюстрация 6.8 : Ground reaction forces during walking vs. time | ||

| + | :Иллюстрация 6.9 : Trolley motion vs. time | ||

| + | :Иллюстрация 6.10 : Hip joint valve duty cycles vs. time | ||

| + | :Иллюстрация 6.11 : Knee joint valve duty cycles vs. time | ||

| + | :Иллюстрация 6.12 : Desired and actual joint angles vs. time: Test 2 | ||

| + | :Иллюстрация 6.13 : Desired and actual x-y foot paths: Kicking motion | ||

| + | :Иллюстрация 6.14 : Desired and actual joint angles vs. time: Kicking motion | ||

| + | :Иллюстрация 6.15 : Calculated angular velocity vs. time | ||

| + | :Иллюстрация 6.14 : Desired and actual joint angles vs. time: Derivative control | ||

| + | :Иллюстрация 7.1 : Desired and actual x-y foot paths: Angle feedback only | ||

| + | |||

| + | ---- | ||

| + | |||

| + | == Глава1 == | ||

| + | |||

| + | <center>'''Acknowledgements'''</center> | ||

| + | |||

| + | I would like to thank my wife Joni for being supportive of this crazy idea to go get a masters degree. Without her support, I never would have been able to do it. I | ||

| + | would also like to thank my wonderful new son Boyd for helping me put priorities into perspective. | ||

| + | |||

| + | I want to thank Roger Quinn for providing an excellent work environment. I have thoroughly enjoyed my experience working in the Biorobotics Lab. I also appreciate his patient and supportive leadership style. | ||

| + | |||

| + | Gabe Nelson has given me invaluable counsel in robotics as well as life. In this thesis, you will see evidence of all the work he has done before me to make my work possible. For this, I would like to thank him. | ||

| + | |||

| + | I want to thank Rich Bachmann, Matt Birch, Jim Berilla, and Yuan Dao Zhang for using their time and talents to help me build the robot. | ||

| + | |||

| + | I would also like to express my gratitude to the other guys in the lab for being sounding boards for my half-baked ideas and providing a good political discussion at the drop of a hat. | ||

| + | |||

| + | I want to express my appreciation to my parents for raising me and giving me direction. I was taught many of the fundamentals of engineering while tinkering in the garage with my dad. | ||

| + | |||

| + | I want to thank Dr. Joe Mansour and Dr. Steve Phillips for serving on my thesis committee. | ||

| + | |||

| + | The work was supported by the Office of Naval Research under grant number | ||

| + | |||

| + | N0014-99-1-0378, and DARPA under contract number DAAN02-98-C-4027. | ||

| + | |||

| + | Finally, I want to thank God for life, and all these wonderful creatures that we study. Even with all our great technology, our understanding of the world is so limited. | ||

| + | As an engineer, His infinite wisdom and designs humble me. Without Him, we are nothing | ||

| + | |||

| + | ---- | ||

| + | |||

| + | <center>'''Design and Control of a Robotic Leg With Braided Pneumatic Actuators'''</center> | ||

| + | |||

| + | <center>'''Abstract by ROBB WILLIAM COLBRUNN'''</center> | ||

| + | |||

| + | <center>'''A Braided Pneumatic Actuator is a device developed in the 1950’s by J.L.'''</center> | ||

| + | |||

| + | |||

| + | McKibben. In recent years, robotics engineers have begun to rediscover these fascinating devices, and use them as actuators for their robots. These actuators exhibit non-linear force-length properties similar to skeletal muscle, and have a very high strength-to-weight ratio. In this thesis, emphasis was placed on understanding the actuator properties so that this knowledge could be used in simulation and control of legged robots. Static and dynamic mathematical models were developed for the actuators, and verified through testing and simulation. A four-degree of freedom robotic leg was designed, constructed, and controlled. The leg provided stable, sensible forward walking for the robot, and was capable of operating 94% passively. Though these actuators have a few limitations, their muscle-like properties including high strength-to-weight ratio, passive characteristics, and self-limiting force properties make them ideal for legged robots. | ||

---- | ---- | ||

| + | '''Chapter I: Introduction''' | ||

| + | '''1.1 Background''' | ||

| − | + | Much ink has been used to explain the benefits of legged locomotion over wheeled locomotion for robots. As with most things, there is always a trade off. A wheeled robot might go faster and be easier to build, but tell it to climb a flight of stairs and its shortcomings become apparent quickly. Upon observation of all the creatures around us, we see the legged design as the locomotion method of choice. The purpose of this thesis, however, is not to show why it should be done, but how it can be done. | |

| − | + | ||

| − | + | Legged locomotion is the beginning of the biologically inspired approach to robotics. However, putting legs on a frame is not enough to have a walking robot. Arguably, the most important part of any motion device is the mechanism that does the moving: the actuators. In the past, CWRU walking robots have used DC motors to generate leg movement. With the move toward physical autonomy (operation without an umbilical), the poor strength to weight ratio of DC motors became far too prohibitive. The next generation of robot used pneumatic cylinders to increase this ratio. Air cylinders’ strength to weight ratio is much better than electric motors, but there is still room for improvement. The total weight of Robot III was 29.5 lbs. with 76% of that being actuator and valve weight (Bachmann, 2000). A lighter weight actuator that was just as strong would increase the robot’s payload capacity. The biologically inspired approach led the group to look at the prime movers that are designed into natural walking “machines”: muscles. Using real muscle tissue is technologically not practical at this time (Shimoyama, 1997), so an artificial muscle is necessary. This actuator is known as a Braided Pneumatic Actuator or a McKibben Artificial Muscle. These actuators can have a power-to-weight ratio as high as 25 times greater than DC motors (Shadow, 2000). These actuators also have experimentally been shown to have force-length properties similar to skeletal muscle (Klute et al.,1999). | |

| − | + | ||

| − | + | [[Изображение:Figure1-1.jpg]] | |

| − | + | ||

| − | + | ''Figure 1-1: The dimensionless relationship between force and length under isometric conditions at maximal activation for various animals as well as a McKibben actuator pressurized to 5 bar (Klute et al.,1999).'' | |

| − | + | ||

| − | + | This muscle-like stiffness and their structural flexibility present real advantages over air cylinders. In this thesis, these braided pneumatic actuators will be referred to as “McKibbens” or BPA. | |

| − | + | ||

| − | + | '''1.2 Purpose and Overview''' | |

| − | + | ||

| − | + | The focus of this project involves the investigation of using McKibbens as the prime mover in a walking robot. This work is divided into six sections. Each chapter builds upon the other to explain the process and methods of using BPA to make a robotic leg walk. Chapter two explains all the properties of the BPA as well as the mathematical model formulated for simulation and control. Chapter three describes the simple spring- mass-damper simulation that was written to dynamically validate the model. This simulation included a model of the actuator, and a model of a solenoid valve for controlling the mass of air in the actuator. The valve states were the only inputs, and the simulation calculated the remaining system properties. The next chapter describes all the hardware involved in making the robot walk. A system overview, the valves, the sensors, and the leg design are all presented. Chapter five delves into the control program and how the sensor feedback is turned into valve commands. Then, chapter six presents the results or quantification of the walking. The last chapter discusses the limits and shortcomings of using McKibbens. Finally, possible solutions and improvements are addressed as topics of future work. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | Figure | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Текущая версия на 03:30, 28 апреля 2009

ПЕРЕВОДИМ_Оглавление

Оглавление

Благодарности

Аннотация

Глава I. ВВЕДЕНИЕ

- 1.1 Background

- 1.2 Purpose and Overview

Глава II. Braided Pneumatic Actuators

- 2.1 Physical Characteristics

- 2.2 Geometric and Static Model

- 2.3 Static Model Verification

- 2.4 Dynamic Model

Глава III. Simulation

- 3.1 Simulation Overview

- 3.2 Equations of Motion

- 3.3 Valve Model

- 3.4 Dynamic Model Verification

Глава IV. Robot Hardware

- 4.1 System Overview

- 4.2 Leg Design

- 4.3 Valves

- 4.4 Force Sensors

- 4.5 Angle Sensors

Глава V. Control

- 5.1 Control Architecture and Control Laws

- 5.2 Control Program

- 5.3 Inverse Kinematics

Глава VI. Results and Discussion

- 6.1 Desired Walking Behavior

- 6.2 Tuning

- 6.3 Walking Results

- 6.4 Robot Limitations

- 6.5 Derivative Control

Глава VII. Conclusion

- 7.1 It Walks!

- 7.2 Semi-Observed Speculation

- 7.3 Future work

Приложение A: Simulation Code

- A.1 Actuator.cpp

Приложение B: Controller Code

- B.1 Control.cpp

- B.2 Def.h

- B.3 Hardware.cpp

- B.4 Predict.dat

- B.5 Gain.dat

Приложение C: Robot Hardware

- C.1 Strain Gage Amplifier

- C.2 Wiring

- C.3 Mechanical Drawings

Литература

Список таблиц

- Таблица 4.1 : Transducer sensitivity and error

- Таблица 6.1 : Joint range of motion

- Таблица 6.2 : Time parameters for walking motion

- Таблица 6.3 : Walking motion control gains

- Таблица 6.4 : Passivity and average duty cycles of each valve

Список иллюстраций

- Иллюстрация 1.1 : Dimensionless force-length properties of actuators and biological muscles

- Иллюстрация 2.1 : Photograph of inflated and uninflated actuators

- Иллюстрация 2.2 : Actuator dimensions

- Иллюстрация 2.3 : Geometric schematic of actuators

- Иллюстрация 2.4 : Mesh geometry

- Иллюстрация 2.5 : Revised actuator geometry schematic

- Иллюстрация 2.6 : Pressure, Length, Force, Stiffness Relationship for a BPA

- Иллюстрация 2.7 : Static model verification schematic

- Иллюстрация 2.8 : Plot of Force vs. Length for a BPA with constant internal mass of air

- Иллюстрация 2.9 : Pressure Increase vs. Length – constant mass system

- Иллюстрация 2.10 : Plot of Force vs. Length – constant air mass – Exp. vs. Theor. results

- Иллюстрация 2.11 : Plot of Effectiveness vs. Pressure

- Иллюстрация 2.12 : Plot of Force vs. Length – Exp. vs. Theor. Results – (effectiveness)

- Иллюстрация 2.13 : Plot of Force vs. Length – Constant Pressure System

- Иллюстрация 2.14 : Dynamic model schematic

- Иллюстрация 3.1 : Simulation overview schematic

- Иллюстрация 3.2 : Detailed simulation schematic

- Иллюстрация 3.3 : Actuator equation of motion schematic

- Иллюстрация 3.4 : Flow curve for Matrix 758 3-way valve

- Иллюстрация 3.5 : Dynamic model verification schematic

- Иллюстрация 3.6 : Length vs. Time – 60 psi constant mass – 6 lb load - measured

- Иллюстрация 3.7 : Length vs. Time – 60 psi constant mass – 6 lb load - simulation

- Иллюстрация 3.8 : Length vs. Time – 80 psi constant mass – 11 lb load - measured

- Иллюстрация 3.9 : Length vs. Time – 80 psi constant mass – 11 lb load - simulation

- Иллюстрация 3.10 : Length vs. Time – 60 psi constant mass – 11 lb load - measured

- Иллюстрация 3.11 : Length vs. Time – 60 psi constant mass – 11 lb load - simulation

- Иллюстрация 3.12 : PWM valve model verification schematic

- Иллюстрация 3.13 : Commanded vs. Actual duty cycles – Matrix 758 3-way valve

- Иллюстрация 3.14 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 5 lb load - measured

- Иллюстрация 3.15 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 5 lb load - simulation

- Иллюстрация 3.16 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 1 lb load - measured

- Иллюстрация 3.17 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 1 lb load - simulation

- Иллюстрация 3.18 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 15 lb load - measured

- Иллюстрация 3.19 : Length vs. Time – 100 psi - 25 Hz, 50% PWM – 15 lb load - simulation

- Иллюстрация 3.20 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 1 lb load - measured

- Иллюстрация 3.21 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 1 lb load - simulation

- Иллюстрация 3.22 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 5 lb load - measured

- Иллюстрация 3.23 : Length vs. Time – 100 psi - 50 Hz, 50% PWM – 5 lb load - simulation

- Иллюстрация 4.1 : Robot hardware schematic

- Иллюстрация 4.2 : Photograph of robot

- Иллюстрация 4.3 : CAD model and photograph of robot leg

- Иллюстрация 4.4 : CAD model and photograph of hip translational joint

- Иллюстрация 4.5 : CAD model and photograph of hip rotational joint

- Иллюстрация 4.6 : Schematic of inlet valve

- Иллюстрация 4.7 : Schematic of exhaust valve

- Иллюстрация 4.8 : Current vs. time for inlet valve

- Иллюстрация 4.9 : Current vs. time for exhaust valve

- Иллюстрация 4.10 : Force sensor classic analysis schematic

- Иллюстрация 4.11 : Force sensor FEA results

- Иллюстрация 4.12 : Photograph of force sensors

- Иллюстрация 4.13 : Photograph of strain gage amplifier

- Иллюстрация 4.14 : Transducer calibration plot

- Иллюстрация 4.15 : Photograph of completed force measurement system

- Иллюстрация 4.16 : Photograph of completed angle measurement systems

- Иллюстрация 5.1 : Labeled schematic of a joint

- Иллюстрация 5.2 : Block diagram of the control algorithm

- Иллюстрация 5.3 : ISR schematic

- Иллюстрация 5.4 : Inverse kinematics schematic

- Иллюстрация 6.1 : Desired foot positions for walking motion

- Иллюстрация 6.2 : Sequential video frames of the leg during walking motion

- Иллюстрация 6.3 : Desired and actual x-y foot paths: Test 1

- Иллюстрация 6.4 : Desired and actual joint angles vs. time: Test 1

- Иллюстрация 6.5 : Actuator force vs. time

- Иллюстрация 6.6 : Desired and actual joint stiffness vs. time

- Иллюстрация 6.7 : Joint torque vs. time

- Иллюстрация 6.8 : Ground reaction forces during walking vs. time

- Иллюстрация 6.9 : Trolley motion vs. time

- Иллюстрация 6.10 : Hip joint valve duty cycles vs. time

- Иллюстрация 6.11 : Knee joint valve duty cycles vs. time

- Иллюстрация 6.12 : Desired and actual joint angles vs. time: Test 2

- Иллюстрация 6.13 : Desired and actual x-y foot paths: Kicking motion

- Иллюстрация 6.14 : Desired and actual joint angles vs. time: Kicking motion

- Иллюстрация 6.15 : Calculated angular velocity vs. time

- Иллюстрация 6.14 : Desired and actual joint angles vs. time: Derivative control

- Иллюстрация 7.1 : Desired and actual x-y foot paths: Angle feedback only

Глава1

I would like to thank my wife Joni for being supportive of this crazy idea to go get a masters degree. Without her support, I never would have been able to do it. I would also like to thank my wonderful new son Boyd for helping me put priorities into perspective.

I want to thank Roger Quinn for providing an excellent work environment. I have thoroughly enjoyed my experience working in the Biorobotics Lab. I also appreciate his patient and supportive leadership style.

Gabe Nelson has given me invaluable counsel in robotics as well as life. In this thesis, you will see evidence of all the work he has done before me to make my work possible. For this, I would like to thank him.

I want to thank Rich Bachmann, Matt Birch, Jim Berilla, and Yuan Dao Zhang for using their time and talents to help me build the robot.

I would also like to express my gratitude to the other guys in the lab for being sounding boards for my half-baked ideas and providing a good political discussion at the drop of a hat.

I want to express my appreciation to my parents for raising me and giving me direction. I was taught many of the fundamentals of engineering while tinkering in the garage with my dad.

I want to thank Dr. Joe Mansour and Dr. Steve Phillips for serving on my thesis committee.

The work was supported by the Office of Naval Research under grant number

N0014-99-1-0378, and DARPA under contract number DAAN02-98-C-4027.

Finally, I want to thank God for life, and all these wonderful creatures that we study. Even with all our great technology, our understanding of the world is so limited. As an engineer, His infinite wisdom and designs humble me. Without Him, we are nothing

McKibben. In recent years, robotics engineers have begun to rediscover these fascinating devices, and use them as actuators for their robots. These actuators exhibit non-linear force-length properties similar to skeletal muscle, and have a very high strength-to-weight ratio. In this thesis, emphasis was placed on understanding the actuator properties so that this knowledge could be used in simulation and control of legged robots. Static and dynamic mathematical models were developed for the actuators, and verified through testing and simulation. A four-degree of freedom robotic leg was designed, constructed, and controlled. The leg provided stable, sensible forward walking for the robot, and was capable of operating 94% passively. Though these actuators have a few limitations, their muscle-like properties including high strength-to-weight ratio, passive characteristics, and self-limiting force properties make them ideal for legged robots.

Chapter I: Introduction 1.1 Background

Much ink has been used to explain the benefits of legged locomotion over wheeled locomotion for robots. As with most things, there is always a trade off. A wheeled robot might go faster and be easier to build, but tell it to climb a flight of stairs and its shortcomings become apparent quickly. Upon observation of all the creatures around us, we see the legged design as the locomotion method of choice. The purpose of this thesis, however, is not to show why it should be done, but how it can be done.

Legged locomotion is the beginning of the biologically inspired approach to robotics. However, putting legs on a frame is not enough to have a walking robot. Arguably, the most important part of any motion device is the mechanism that does the moving: the actuators. In the past, CWRU walking robots have used DC motors to generate leg movement. With the move toward physical autonomy (operation without an umbilical), the poor strength to weight ratio of DC motors became far too prohibitive. The next generation of robot used pneumatic cylinders to increase this ratio. Air cylinders’ strength to weight ratio is much better than electric motors, but there is still room for improvement. The total weight of Robot III was 29.5 lbs. with 76% of that being actuator and valve weight (Bachmann, 2000). A lighter weight actuator that was just as strong would increase the robot’s payload capacity. The biologically inspired approach led the group to look at the prime movers that are designed into natural walking “machines”: muscles. Using real muscle tissue is technologically not practical at this time (Shimoyama, 1997), so an artificial muscle is necessary. This actuator is known as a Braided Pneumatic Actuator or a McKibben Artificial Muscle. These actuators can have a power-to-weight ratio as high as 25 times greater than DC motors (Shadow, 2000). These actuators also have experimentally been shown to have force-length properties similar to skeletal muscle (Klute et al.,1999).

Figure 1-1: The dimensionless relationship between force and length under isometric conditions at maximal activation for various animals as well as a McKibben actuator pressurized to 5 bar (Klute et al.,1999).

This muscle-like stiffness and their structural flexibility present real advantages over air cylinders. In this thesis, these braided pneumatic actuators will be referred to as “McKibbens” or BPA.

1.2 Purpose and Overview

The focus of this project involves the investigation of using McKibbens as the prime mover in a walking robot. This work is divided into six sections. Each chapter builds upon the other to explain the process and methods of using BPA to make a robotic leg walk. Chapter two explains all the properties of the BPA as well as the mathematical model formulated for simulation and control. Chapter three describes the simple spring- mass-damper simulation that was written to dynamically validate the model. This simulation included a model of the actuator, and a model of a solenoid valve for controlling the mass of air in the actuator. The valve states were the only inputs, and the simulation calculated the remaining system properties. The next chapter describes all the hardware involved in making the robot walk. A system overview, the valves, the sensors, and the leg design are all presented. Chapter five delves into the control program and how the sensor feedback is turned into valve commands. Then, chapter six presents the results or quantification of the walking. The last chapter discusses the limits and shortcomings of using McKibbens. Finally, possible solutions and improvements are addressed as topics of future work.